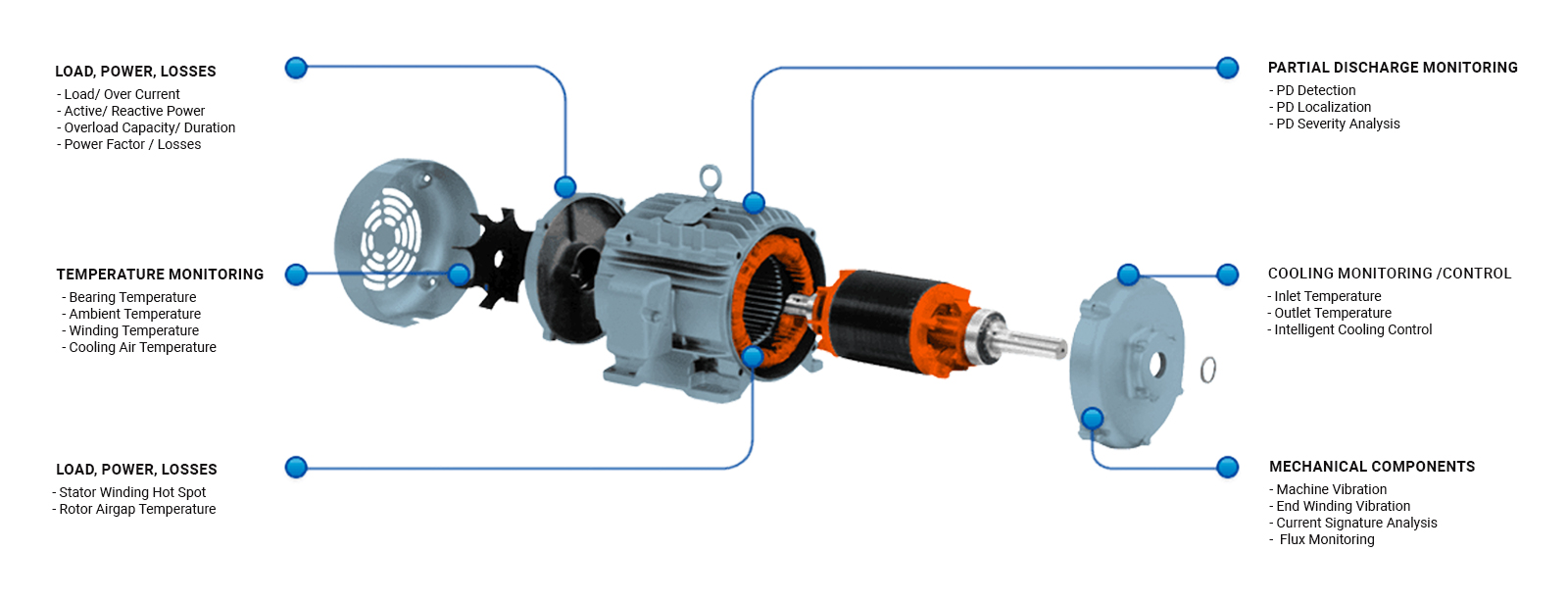

Turnkey Monitoring solution with greater diagnostic capability to analyze crucial parameters of rotating machines. The system can perform Current Signature Analysis, Partial Discharge Monitoring, Temperature Monitoring, Vibration Monitoring, Flux Monitoring, Air Gap Monitoring.

Partial Discharge Testing and Monitoring prevents motor failures due to insulation defects in stator windings; helps is performance optimization of motors.

Online monitoring of Temperatures into Motor such as Winding, Bearing, Cooling Air Temperature, and Ambient Temperature etc.

Stator Winding Hot Spot and Rotor Air Gap temperature monitoring enable performance optimization, failure prevention, and life-time extension.

A complete condition monitoring includes monitoring all electric and mechanical properties of Generator, i.e., Load, PF, Flux, Vibration & Current Signature Analysis.